Industrial 3D Printing: How Companies Are Streamlining Production with Advanced Printers

Additive manufacturing is popularly known as industrial 3D printing, which is driving the transformation in the production process in different industries as it allows easy, precise and effective fabrication of parts. 3D printing is different from the traditional techniques in the sense that it creates components in an additive manner that is layer by layer hence easy and fast prototype development, wastage of materials is minimized and intricate designs of parts which would have otherwise been impossible to manufacture created. The processes of industrial 3D printer companies have become more efficient and less expensive as this technology has been integrated. Below are ten facts on how it transforms production.

1. Prototyping and Product Development Take Less Time than Before

Prototyping with 3D printing technology introduces one very useful feature, which is getting rid of expensive moulds and tools. Companies can rapidly design, engineer and manufacture functional prototypes. Because of this, the life cycle period of the product shrinks and the product can go to the market quicker since it is possible to alter the design before actual manufacturing begins. Furthermore, the benefits of 3D printing tend to lower industrial setup verticals and focus on developing small volumes of product making such processing efficient.

2. Mass Customization

Another advantage of 3D printing for industries and businesses is flexibility, therefore it is possible to manufacture even bespoke products and components, which is useful in industries such as healthcare or car manufacturing. One can design and manufacture adjustable prostheses, specific body implants, and even special car components with unique and distinct sizes and shapes all within a manufacturing unit. The technology also allows for rapid modification and enhancement owing to dynamic consumer trends and is ideal for the business this technology is used.

3. On-Demand Production and Reduced Lead Times

Thanks to 3D technology, the organization can make the components only when they are needed which eliminates the need for storing too many goods and subsequently reduces the shipping durations when the products are in high demand. This benefit allows firms to adjust for variations in needs more easily without incurring storage expenses or delays associated with printing in overseas countries. In addition, on-demand production management lessens the chances of anticipating demand inappropriately and thus minimizes waste practices of production and storage.

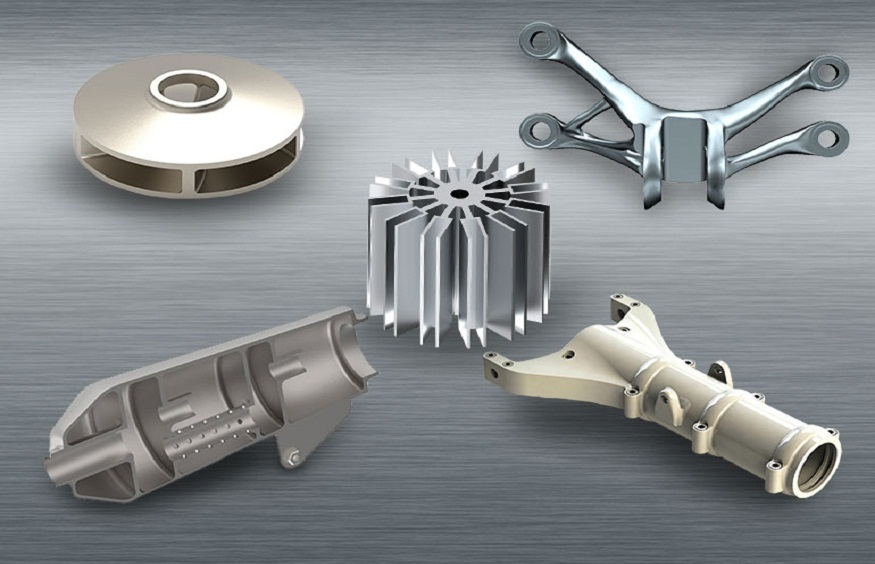

4. Complex Geometries and Design Freedom

While traditional ways of manufacturing have limitations when it comes to geometrical designs of products, 3D printing can achieve such features by making internal features (structures) such as channels or lattice designs. This allows one to make strong and lightweight components that in turn enhance the efficiency and efficacy of the product. Traditional instruments impose limits on the designers, but this is not the case anymore as newer tools can give designs that are more complex therefore making functional parts with lesser weights even in very critical applications.

5. Reduced Material Waste

3D printing is a more efficient process in terms of material compared to the traditional processes where excess materials are usually used. This is important for those industries that deal with limited or costly raw materials as it helps in making the production process more economical and environmentally friendly. Lastly, because production is done through a layer-by-layer approach of building up the model, 3D Solutions aids in eliminating waste production and helps in combating the negative effects of production on the environment which fits into the increasing sustainability agenda in business.

6. Lower Production Costs

Although 3D printing involves some cost at the very beginning, it is advantageous in the long run as it does away with the need to have moulds, tooling, and even huge assembly lines which cut down production costs. It is most economically justifiable in cases of small or low-volume production where most other methods would be cost-prohibitive. Also, because much of the 3D printing process is automated, there is less expenditure on manpower as well as time spent on carrying out manual work which further results in a reduction of costs.

7. Supply Chain Resilience

3D printing enhances the resilience of the supply chain by removing the geographical boundaries of production. Parts may be printed on location or at least closer to where they are utilized, therefore minimizing the long-haul reliance for shipping and ensuring there is provision in case of disruption or delays of the global supply chains. This ability ensures that organizations can quickly adjust when certain goods are unavailable or when there are disturbances in the flow of goods which provides enhancement in the manageability of the production system.

8. Tooling and Spare Parts Production

3D printing technology is suitable for manufacturing replacement components and tools, especially those which are for older and hard-to-find machines. Companies can print their parts instead of waiting thus minimizing the downtime period and allowing the machines to run without the need for an external contractor. This aspect is convenient, especially in sectors where the components of the machines are obsolete or too costly to produce by conventional means.

9. Enhanced Supply Chain Collaboration

The exchange of digital files of the parts enables businesses to work more closely with suppliers or manufacturers. This type of communication reduces errors and expenses, increases the speed of the manufacturing process, and guarantees that the production is in line with the most current designs. In addition to reducing the time to adjust and enhancements of products, real-time interaction helps in making sure that each of the supply chain partners is working with the most recent data and parameters.

10. Innovation in Product Development

In design 3D printing has innovation potential because the designers can afford to use bizarre and intricate designs. The ability to produce components in bespoke form inspires ingenuity, and consequently, more functional elements and entirely new products are created, which is a promising trend for the future. It’s anticipated that with the evolution of technology, 3D printing will do more in the enhancement of product design and manufacturing.

Industrial 3D printing is forging redevelopment in a way that has allowed the use of complicated designs, improving material efficiency, controlling costs and improving the supply chain so that it is more flexible. Thus, the nature of the product development process that companies engage in will be similarly rendered effortless and help the firm to cope in the existing competitive environment with the use of the best 3D printer for architects and other professionals. 3D printing, whether to allow for quick product development, provide specialized components or low-volume manufacturing, is leading to an era of enhanced serviceability and creativity in production.